Osmosis

The term ‘osmosis’ was coined in the early 70s to describe the blistering found on many GRP boat hulls, and is now in common usage.

A GRP boat hull is a usually a mixture of polyester resin reinforced with glass fibres, created in layers which forms a laminate. This laminate will have small voids, air pockets and microcracks within the resin and at the interface between the resin and the glass fibres. Water diffuses into and passes through the gel coat and the laminate as water molecules, not a liquid. Water may pass slowly through a GRP hull in this way, or the water molecules can collect and condense within these voids. Within the voids/laminate are various water soluble components. These are solvents and unreacted constituents from the manufacturing process.

The water within the voids dissolves and reacts with these components. (hydrolysis). The ongoing hydrolysis will continue within the voids, enlarging the cavities and forming a solution. The solution is water-absorbing (hydroscopic) and once the solution is released in the voids it accelerates the rate of water absorption into the laminate. This process will not be reversed by taking the boat out of the water.

As this continues, the voids are increased in size and the pressure within increases. At some point the pressure may become too high for the surrounding material to support and a blister is formed. As this process continues, moisture continues to be absorbed, the laminate breakdown accelerates and more blisters are formed.

In time some larger blisters may develop within the laminate, as well as those more commonly occurring between the gel coat and laminate. Eventually at this stage, treatment will be required as the structural integrity of the hull can be affected.

A bit more on Osmosis

No yacht has sunk from osmosis, but big blisters will weaken the laminate. The water and the contaminants in the laminate have to be removed. Whilst drying will remove the water, it leaves many of the contaminants behind, so for this reason steam cleaning and washing the hull surface is important but not sufficient.

Depending on how big and how many blisters you have, the decision on how much work is down to you. A few isolated blisters can be carefully cut off with a chisel, washed out and filled with epoxy resin. Even large blisters can be treated this way.

Peeling the gel coat is common but extreme and on its own often adds to problems. Blisters will return, even after peeling. If there are still voids in the laminates and uncured gel coat, more blisters will occur.

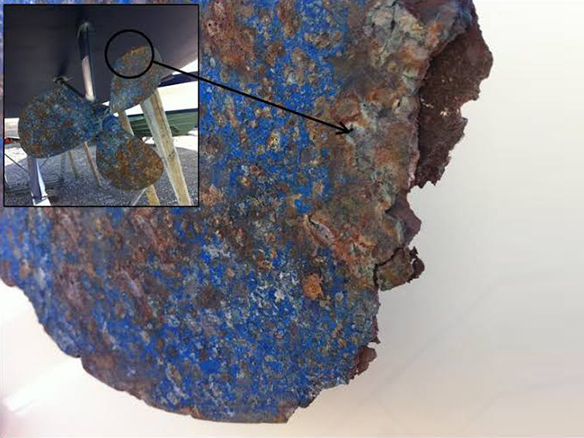

Cathode Protection

If you have two different metals physically or electrically connected and then you immerse them in sea water, they become a battery. Some current flows between the two metals, and the electrons that make up that current are supplied by one of the metals giving up bits of itself, in the form of metal ions, to the seawater. This is called galvanic corrosion and can destroy underwater metals. The obvious casualty is the bronze or aluminium propeller on a stainless steel shaft.

In order to counteract galvanic corrosion you need to add a third metal into the circuit, one that gives up its electrons first. This piece of metal we call a sacrificial anode, and usually it is zinc. It cannot be emphasised enough the importance of maintaining the zinc anodes on your boat. When an anode is dead, the metal component it was installed to protect begins to die.

A professional yacht surveyor will check your yacht has cathodic protection.

Things to keep in mind

The larger the surface area of a zinc anode the more protection, although this does depend on the metal it is protecting.

Check your anodes at least annually and replace those that are half depleted.

For protection it is CRUCIAL that an anode must be in electrical contact with the metal being protected. Low-resistance, metal-to-metal contact is required, so you can either do it by mounting the zinc directly to the metal being protected or connect the two with a wire. Ensure that when an anode is mounted directly to the protected metal, e.g., bolted to the side of a metal rudder, the surface that the anode is connected to must be bare and bright. Do not paint anodes.

Skin Fitting Failures

There is a good article here, credited to Marine Surveys UK on issues with skin fittings.

Some Good Old Rot

Here are some pictures of good old fashioned rot.